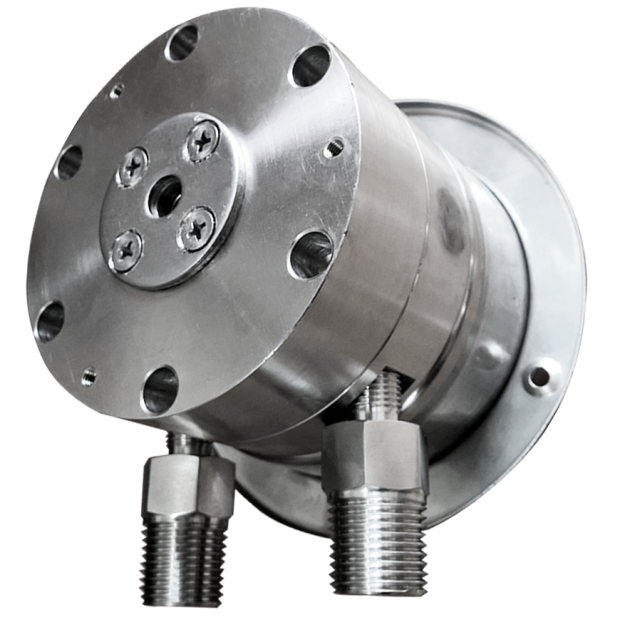

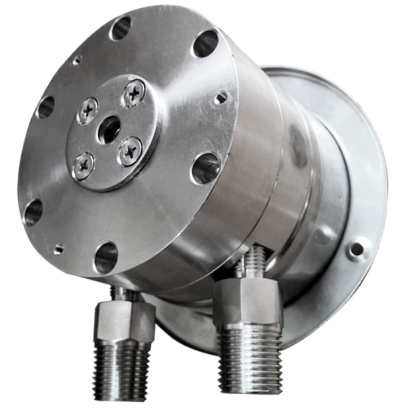

Model: MDI-SDDB

Introduction

MDI-SDDB differential pressure gauge measuring principle adopts single diaphragm and dual bellows.

MDI-SDDB is suitable for same or different pressure sources measurement in non-crystallized and nonsolidified liquid, gas and steam that compatible with connection’s material.

Features

■ OEM service

■ Pressure sensor adopts single diaphragm and dual bellows

■ Various installation types for selection

■ All stainless steel design

■ Maximum static pressure 40 bar

■ Oil-filling, Install switch contact, install diaphragm seal or capillary are available for various environment application

■ Shockproof type available (option)

Main Specifications

▼Size

4”, 6”

▼Installation type

Bottom mount (A) / Bottom mount with back flange(B) / Back mount (ADC) / Back mount with front flange

(BDC)

▼Window

PC / Glass

▼Pressure connection

Material: SS304

(Option: SS316)

1/2”NPT male / female thread

▼Thread hole pitch

54mm (standard)

Other length available upon request

▼Differential pressure range

Min.: 50 kPa

Max.: 5000 kPa

▼Applicable fluid

Non-crystallized or nonsolidified liquid and gas that compatible with connection's material

▼Ambient temperature

Normal:-20°C to +60°C

Glycerin filled: +10 to +60°C

▼Fluid temperature

+60°C

▼Liquid-filling

Dry

Glycerin

Silicone oil

▼Protection level

IP54 (option: IP65)

Other Specifications

▼Ring

Stainless steel

▼Case

SS304 (Option: SS316)

▼Pointer

Aluminum with black enamel

▼Dial face

All black scale on whiteboard

Specially designed dial face for differential gauge

▼Measuring elements

Single diaphragm & Dual bellows

Material: SS316

▼Movement

Stainless steel dampened movement

▼Accuracy

Standard: 2.5%

(Option: 1.6%)

▼Operating pressure

Stabilization: 0.75* full scale

▼Maximum static pressure

40 bar

▼Other requests (Option)

Third party notarized document

Inspection report

Tag

Customized dial face (scale, color, etc.)

Install diaphragm seal

Install switch contact

Coating

Install armored capillary

Download